Mercury Waste 2 Energy is a division of Mercury Consultancy, a UK Company which specializes in providing a combined Power and Recycling Plant.

Our company holds the exclusive international rights to market and sell Advanced Recycling and Energy Recovery (AREC) Plants which constitute both Plastics to Diesel and Gas Pyrolysis Technology Plants on behalf of its partners Prestige Thermal Energy (PTE).

Our partners PTE hold the International Patent rights of both design and manufacture of the equipment.

Our plants use proprietary technology developed by PTE, world leaders in thermal conversion. The Pyrolysis technology used offers multiple advantages over any other technologies and therefore is far superior to either Waste Incinerator or Plasma Gasification Plants.

Is to address the ecological and environment issues of our planet. Today one of the most pressing environmental issues for mankind is how to eradicate our waste safely without any harm to Mother Earth.

“Our Solution to this pressing problem is to use an advanced form of Pyrolysis, an existing technology”

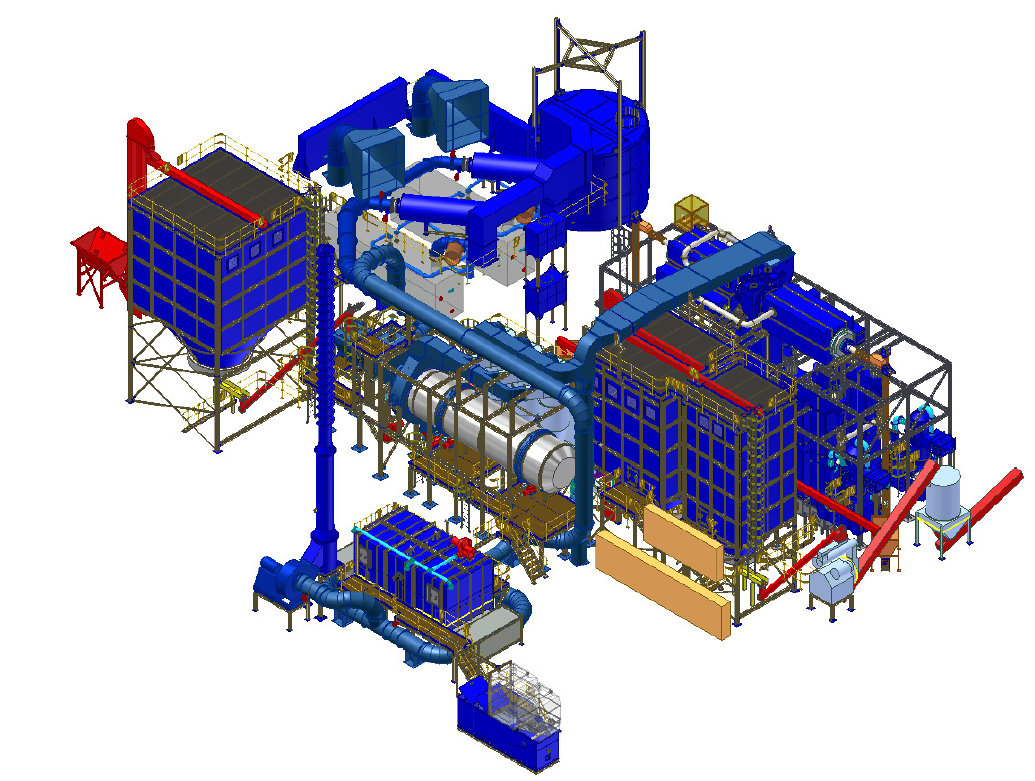

A Diagrammatic View of a Waste 2 Energy Plant

To define Pyrolysis technology in simple terms is to convert organic waste into tiny particles which we call cellulose fibre and these particles are passed through our Pyrolysis Tower, within micro seconds the particles are transformed into Synthetic Gas. The conversion process is totally confined within a vacuum.

Thereby two important green issues are implemented automatically:

a) Our advanced technology does not create any harmful emissions or pollutants like Furans or Dioxins because there is no oxygen in the system. 1 The pollutants mentioned can only be created if you burn the waste material using oxygen. Waste Incinerator or Plasma Gasification Plants create these dangerous pollutants because they are burning the waste material at a temperature of over 1250 degrees centigrade. Both these pollutants are created once the fire temperature exceeds 1100 degrees centigrade.

Dioxins and furans are carcinogenic - persistent substances that do not readily break down in the environment. Health concerns and intake limits Long-term, low-level exposure of humans to dioxins and furans may lead to the impairment of the immune system, the impairment of the development of the nervous system, the endocrine system and the reproductive functions. Short-term, high-level exposure may result in skin lesions and altered liver function. Exposure of animals to dioxins has resulted in several types of cancer.

b) Over 90% of waste material using our technology is converted to Syn Gas and the little residue that is left is totally inert and sterile. The waste residue can then be sold on the open market as fertilizer.

The Syn Gas that is produced can be used to run gas turbines to generate electricity or it can be bottled at 6 bar pressure into gas cylinders for use in domestic homes in the form of cooking gas.

The main advantages of our technology compared to Plasma Gasification or Waste Incinerator Plants are:

A typical Pyrolysis Gas Plant can accommodate from as little as 500 tons per day of organic waste and up to 5000 tons per day of waste. If we use the least amount of waste a city produces of say 500 tons per day, then this is converted to a minimum of 6 tons of Syn Gas per hour. This is equivalent to approx. 500 Gas Cylinders of 12KGS produced per hour.

Our plants run continuously on 24/7 basis throughout the year. There are 8760 hours in a year and using a formula of 8000 hours per year we would be able to produce approx. 4 million gas cylinders to be used in the domestic market.

A typical Pyrolysis Diesel Plant can accommodate 12 tons per day of LDPE plastics such as used carrier bags or plastic bottles. This will produce of a minimum of 384 litres of Diesel per hour plus a further 48 litres of kerosene (Jet Fuel) and 48 litres of Heavy industrial fuel per hour.

What is a Waste 2 Energy Pyrolysis Plant?

Waste 2 Energy (Pyrolysis) plant works by taking the waste and converting into any type of useful energy. The three main forms being heating, electricity or transport fuels. As coal, oil or gas are used today as fuels in fossil fired power stations.

A Pyrolysis Plant uses advanced thermal technology that can convert all types of different organic waste in the absence of oxygen – breaks down all waste into synthetic gas (Syn Gas). By using our advanced pyrolysis technology, our Power Plants can turn all organic waste into clean, emission free renewable green energy and thereby removing all harmful pollutants. The Pyrolysis Technology can be used with different types of waste sources:

The only condition is that the waste type / fraction must be either combustible and / or biodegradable

Our technology solves and improves the current methods of waste management, principally landfill and waste incineration. Both of these methods release dioxins, furans and other pollutants into the earth’s atmosphere.

It is important to note that a Pyrolysis Plant is not the same as an “incinerator” and it is highly misleading to describe it as such. An incinerator is purpose built to reduce the volume of waste by burning (incinerating). This produces a mixture of ash, char’s and tar’s. Furthermore, a waste incinerator plant will burn 60% of the waste and the remaining 40% will be useless as ash plus more importantly this residue is highly toxic. Disposal of the contaminated ash residue is harmful to mankind.

A Pyrolysis Plant, by contrast, is purpose built to provide usable energy and is designed with negligible inert residue

The other major benefit of Pyrolysis Plant is that the Syn Gas produced can be used directly, to fuel a gas turbine generator / engine to create electricity.

Our High–Tech Technology is capable of collecting a diverse range of “waste” products and converting them to gas (Syn. Gas) through a process known as pyrolisation. The gas generated through this process can then be utilized to power special gas engines which convert this Syn. Gas to “green electricity”. This process must not be confused with incineration as our technology does not create any harmful pollutants whereas incineration creates harmful side products known as Dioxins and Furans.

Our role at Mercury Consultancy is to provide the technical knowledge of constructing and implementing a Waste 2 Energy Power Plant from beginning to end for our clients. Our highly skilled professionals will analyse the waste streams available to them and plan, construct and advise on the size of the project. Through this scientific approach we at Mercury Consultancy can provide the correct management information required and confirm the potential income that can be generated by a W2E facility

This process of Waste Management and Conversion Has a Number of Benefits including…

Energy-

Recycling-

Emissions-

Employement-

New Landlfill-

Existing Landfill-

Continuous renewable, green energy.

A more efficient and focused method of recycling.

Elimination of harmful emissions.

Creation of new employment in the construction, operation and maintenance of a facility.

Dramatic reductions in land fill requirements.

These sites can be opened and their contents disposed of in an environmentally friendly manner. The land can then revert to its prior use or be used in some other manner.

The Plant shown consists of 2 Autoclaves; in feed and Separation Plant; 1 Dryer; 2 Pyrolisers Towers and 4 Gas Engines. The layout of the Power Plant is detailed above.